Volkswagen Group of America signed an settlement to collaborate with Redwood Material to recycle the batteries from the group’s rising fleet of battery-electric automobiles it sells in North America.

“For Volkswagen, going all-in on electrification means driving sustainable solutions at every turn,” mentioned Scott Keogh, president and CEO, Volkswagen Group of America Inc.

“Redwood Materials is a great partner to help us accelerate EV adoption in America. This collaboration allows us to move closer toward our goal of closing the loop for a circular EV economy, giving American consumers yet another reason to go electric.”

VW newest to ink a deal

Founded by JB Straubel, the previous Tesla CTO, Redwood Materials signed an settlement on recycling batteries from Toyota in June and agreed to the same cope with Ford Motor Co. in September 2021. It additionally signed an settlement with Tesla in February 2021. Redwood Materials relies in Carson City, Nevada.

The Volkswagen of America Group mentioned the brand new EV battery recycling collaboration might be aided by VWGoA’s nationwide community of roughly 1,000 sellers, beginning with the Volkswagen and Audi manufacturers.

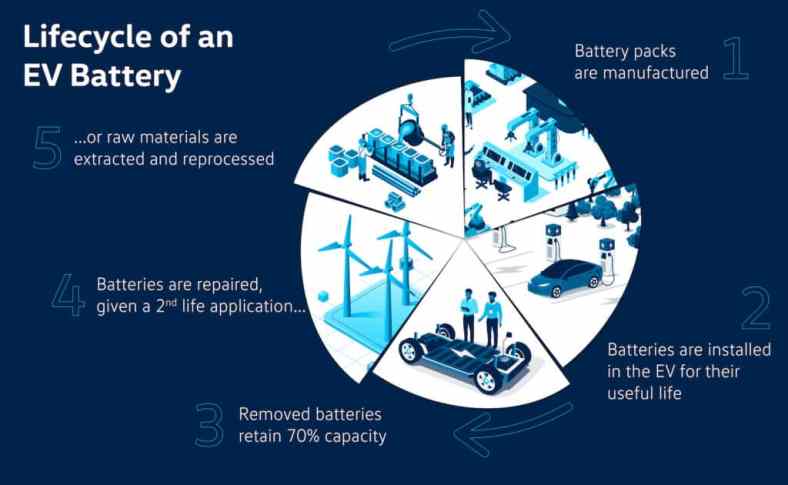

The key to the collaboration is a complete method aimed on the reuse of battery elements. The collaboration will help native battery capability and experience as Volkswagen continues its transition to an electrified portfolio.

Agreement bolsters Volkswagen Group’s EV plans

Volkswagen Group manufacturers plan to introduce greater than 25 new battery electrical automobiles to American customers by means of 2030, accounting for 55% of the group’s complete gross sales.

In addition, the brand new EV battery recycling collaboration will combine prototype batteries from Volkswagen’s analysis services such because the Battery Engineering Lab in Chattanooga. Redwood Materials will work to determine end-of-life batteries and supplies, after which safely bundle and transport them to its Nevada services for recycling

“The electric transformation means making commitments in many areas throughout our business,” mentioned Daniel Weissland, president, Audi of America. “In addition to our robust line-up of fully electric Audi e-tron models available now, having like-minded partners like Redwood Materials in place to further reduce environmental impact throughout the lifecycle of every electric vehicle is critical.”

Each yr, Redwood already recycles greater than 6 GWh of lithium-ion batteries, the equal of 60,000 EV batteries, in Nevada.

Redwood’s course of

The batteries that come to Redwood are composed of end-of-life shopper units, battery manufacturing scrap, and electrical automobile batteries, representing most lithium-ion batteries recycled in North America right this moment.

Redwood has developed processes to extract uncooked supplies resembling cobalt, copper, nickel, and lithium, refines and remanufactures them into crucial battery elements, anode copper foil and cathode, earlier than delivering these merchandise again to home battery cell producers.

“The transition to electric transportation and clean energy is coming and the batteries powering these technologies present an incredible opportunity. As more and more batteries reach end-of-life each year, an increasing and infinitely recyclable resource becomes available,” mentioned Straubel.

“Redwood and Volkswagen Group of America share a vision to create a domestic, circular supply chain for batteries that will help improve the environmental footprint of lithium-ion batteries, decrease cost and, in turn, increase access and adoption of electric vehicles,” he mentioned.

Source: www.thedetroitbureau.com